At Silverscreen Decoration & Fulfillment, innovation isn’t just a buzzword—it’s the foundation of everything we do. We’re constantly investing in technology, expanding our capabilities, and refining our processes to offer more customization and flexibility for our clients. The result? Smarter workflows, better quality, and a wider range of decoration possibilities.

We’re excited to officially introduce two new additions to our screen print department: oversized printing and simulated process printing. These advanced techniques give your designs more room to shine—both literally and creatively.

We know how difficult it can be to find a single shop that does it all—and does it well. That’s why Silverscreen is built to be your one-stop shop for premium decoration. Our team is made up of specialists trained in focused areas of decoration, ensuring that your project is handled with expert precision every step of the way.

By adding oversized and simulated process printing to our lineup, we’re breaking through previous limitations in screen print sizing and color counts—opening the door to a new level of creative freedom for your clients.

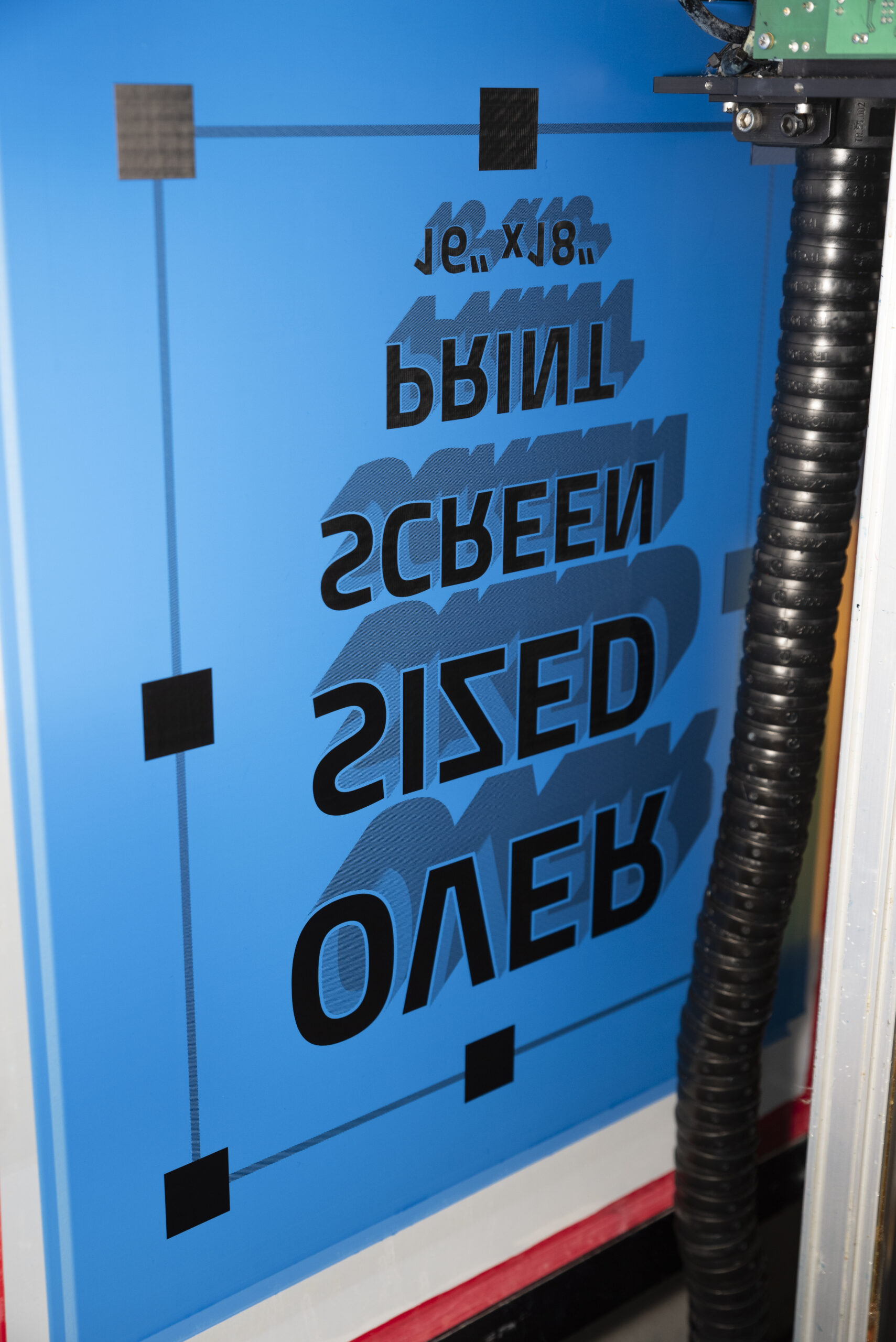

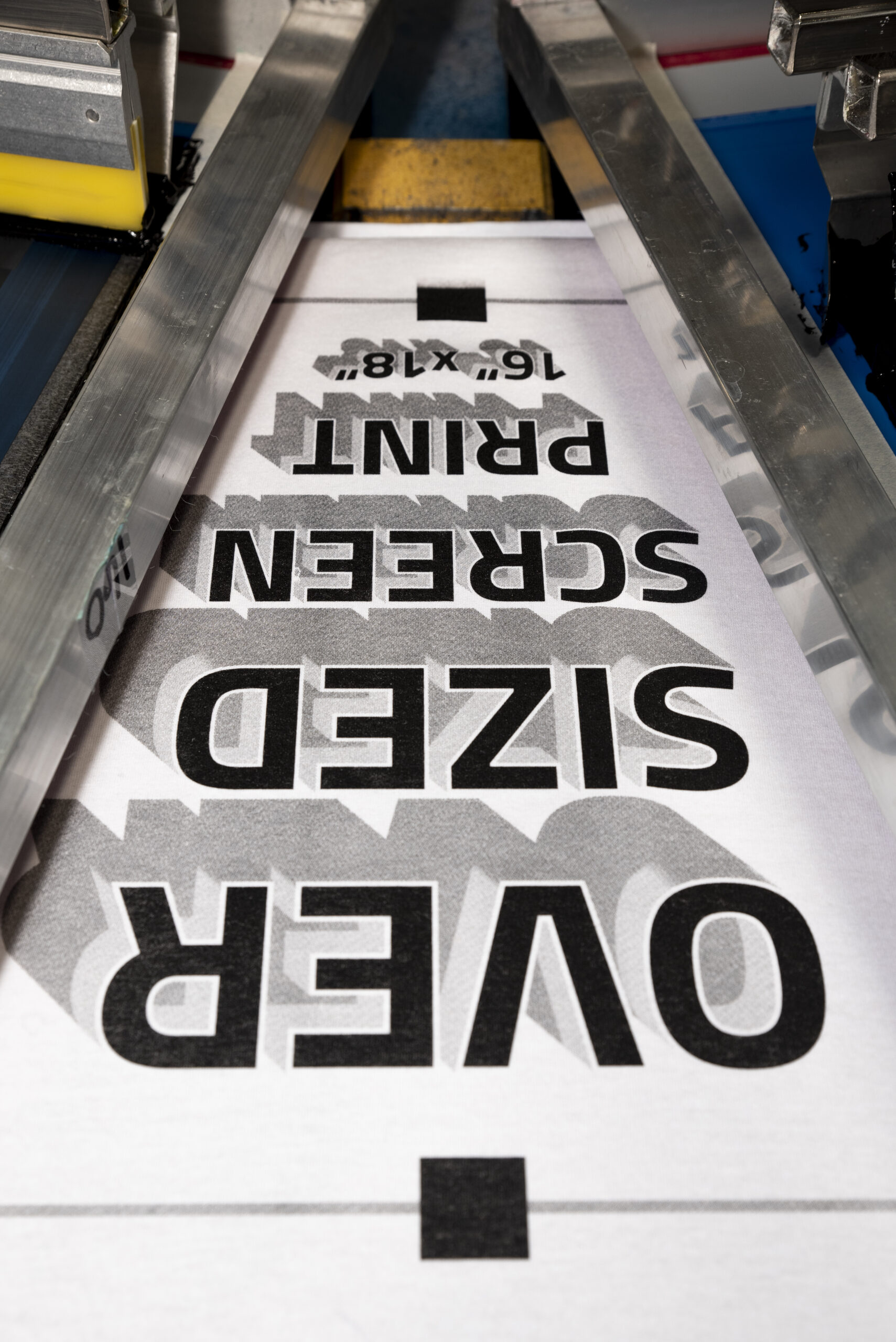

Oversized Printing: Built for the Streetwear Era

2025 marked a new phase in our shop’s evolution. We began the year with a focused initiative to expand our equipment and bring our screen printing capabilities up to speed with the trends we’re seeing in fashion today—particularly the dominance of heavyweight, oversized, and streetwear-inspired garments.

These garments come with larger imprint areas—wider fronts, longer backs, roomier sleeves—and require a print method that scales to match. With our updated setup, including larger squeegees, flood bars, and specialty boards, we can now accommodate larger print areas at just a 15% cost increase over standard prints. Now, Silverscreen can print up to 16” w x18” h (previously 14” w x17” h) for bold, eye-catching designs. Small upgrades on our end mean big creative wins for you and your clients.

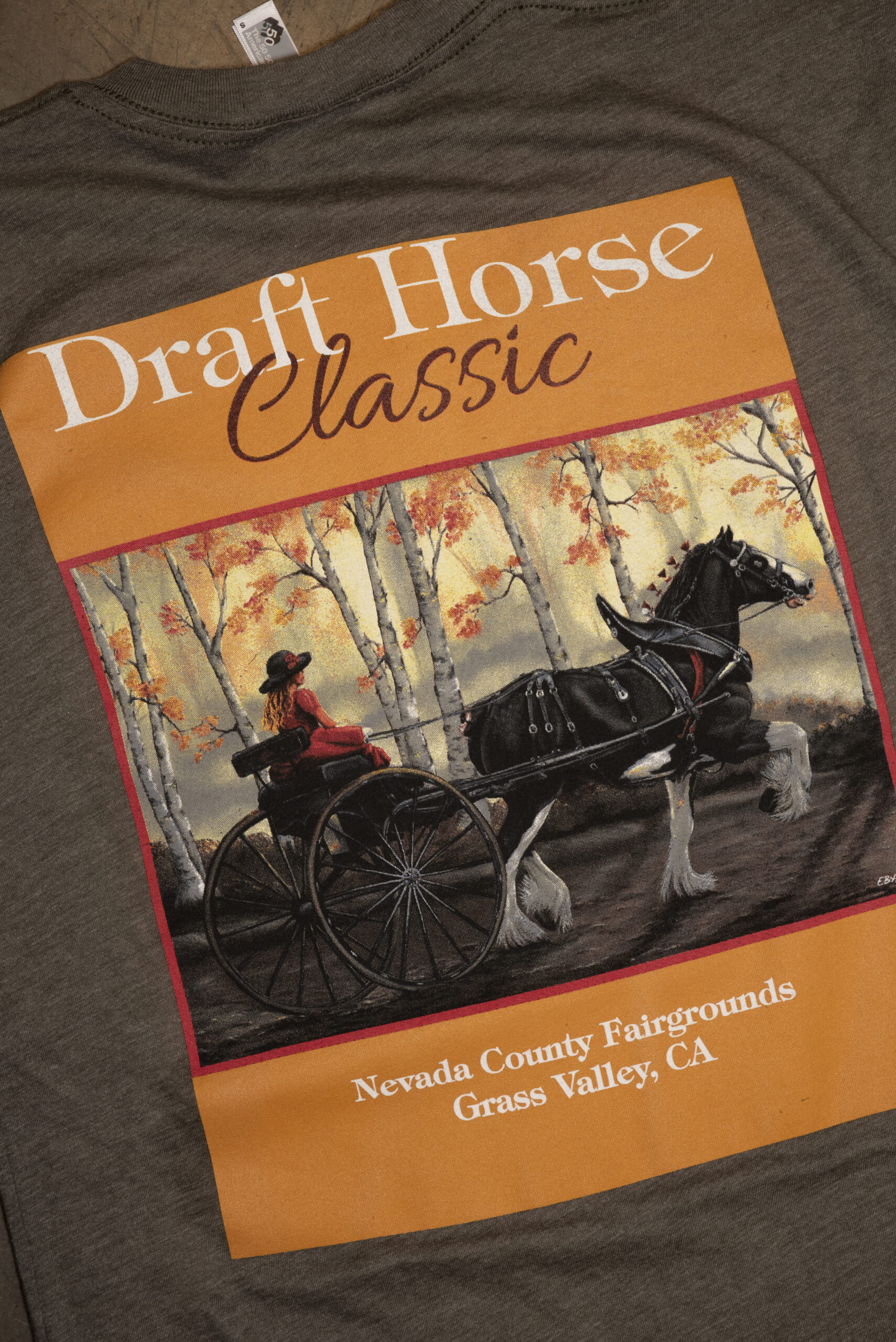

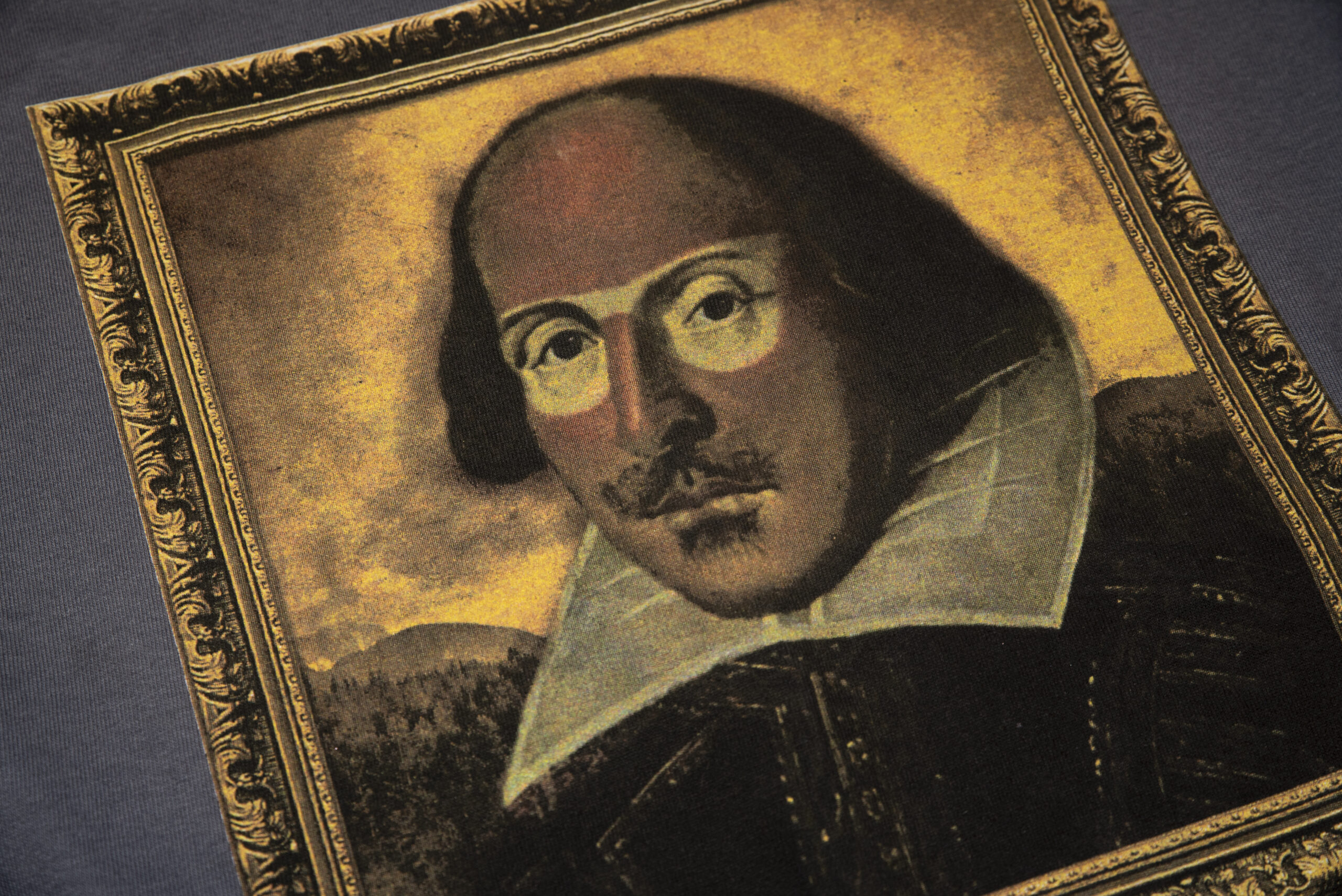

Simulated Process Printing: The Answer to High-Color Artwork

The rise of AI-generated and digitally complex artwork has introduced new challenges in traditional screen printing, especially when it comes to color limitations. Enter simulated process printing.

Simulated process printing uses halftones, spot colors, and gradient effects to mimic full-color designs with fewer screens. This allows us to recreate vibrant, high-detail designs that once exceeded our 9-color max—all while retaining that classic screen print look and feel. We’ve invested in new software that streamlines the art separation process, turning intricate, multi-colored designs into clean halftone layers for precise, high-quality printing. This means faster turnaround, more accurate reproduction, and stunning results.

For artworks with more than 12 colors, simulated process orders incur a 9% price increase per additional color. Pricing is based on the original color count of the artwork before separations, and we highly recommend a pre-production sample for these projects to ensure you’re thrilled with the final outcome.

Simulated process printing is perfect for high-color-count designs—especially when your client prefers the feel of screen print but doesn’t want to compromise with digital techniques like DTF or DTG. It’s the ideal middle ground: complex color, authentic texture.

Innovation Is in Our DNA

Every upgrade we’ve made—from expanding equipment to adopting advanced design software—is about saying YES to more. More creativity. More flexibility. More opportunities to grow your business and exceed your clients’ expectations.

At Silverscreen, we’re committed to staying ahead of trends and technology so you can offer the best decoration services—all from one PO, all under one roof.

Let’s keep creating, evolving, and pushing the boundaries of what’s possible in decoration—together.